Invest in Research and development for innovative growing techniques or new product formulation.

Author: admin

-

5. RECONSTRUCTION OF THE GROW ROOMS (Aug. 2025)

To improve the grow room, more light is needed and the building structure needs to be reinforced. This means that heavier poles need to be purchased and a larger window needs to be made. The costs of this amount to a total of around 250 euros (= 2556 Zimbabwe gold)

-

4. INCREASE OF PRODUCTION (Aug. 2025)

Scaling production, From September we want to double the production to 100bags .The plan is that my two brothers will work for the mushroom farm for about 60-80 hours per month in addition to their other regular work. I am full-time entrepreneur myself working on the mushrooms. The total number of available hours will then be 300 hours per month and the expectation is that an average of 210 kg per month can be produced. For the next production period we want to achieve a productivity of 0.7 hours per kg of oyster mushrooms

-

3. BRANDING MATERIAL / PACKAGING /STICKERS (Aug. 2025)

After the first harvest, steps are taken to professionalize branding and packaging. For this, we publish our activities on social media and purchase packing boxes and stickers.

-

2. REGISTRATION OF MUSHROOM NESTS (Aug. 2025)

In August 2025, the application for registration of the company “Mushroom Nests” is planned to be sent. The application is expected to be effected in August 2025.

-

1. FAMILY BUSINESS (Jul. 2025)

My two brothers Tinotenda and Takudzwa, who always help me with work around the mushroom house can be my partners with each their responsibility from substrate preparation, taking care of the gardens, packaging and marketing and sales to ensure a steady farm that can keep operating consistently even when one or two people are unavailable.

-

7. PRODUCTION AND HARVEST OF FIRST CYCLE (JUNE-JULY 2025)

The first harvest began in June and concluded in July. Although the yields were limited, they were of high quality. Throughout this initial growing cycle, we gained valuable experience, which gives us confidence as we plan to expand production. Additionally, we established contacts for selling fresh oyster mushrooms in local markets and built relationships with key buyers.

-

6. MAKING SPAWN RUN SUBSTRATE (May 2025)

Cotton husk and Wheat straw was the main ingredient used as the substrate, though rice bran was included alongside some other ingredients, including but not limited to brown sugar, limestone, etc which then went through a series of processing steps to make it suitable as a growing medium for the farming oyster mushrooms. After the substrate is prepared, mycelium is added and spawn obtained.

-

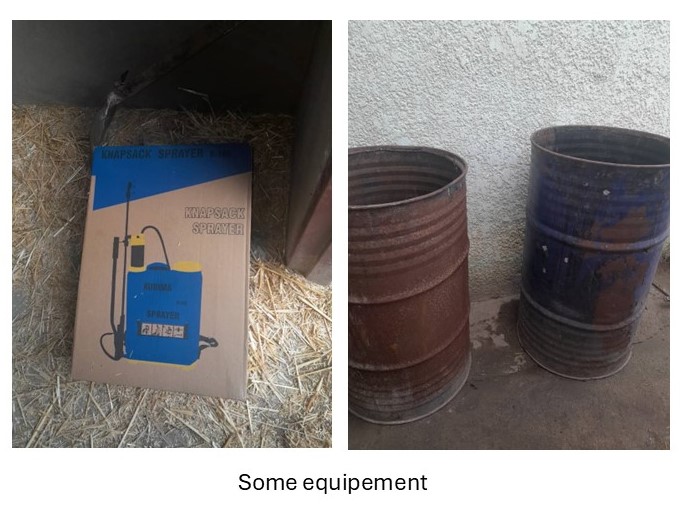

5. EQUIPMENT & FARM SETUP (April 2025)

After receiving funding from Skills and Business for Africa, materials for the mushroom farm were purchased. These included a metallic drum, knapsack sprayer, firewood, twine, bundles of metallic nets, wood, planks, cotton husk and wheat straws . For the farm setup, the walls were plastered and a new, suitable door was installed. To ensure proper darkness in the dark room, thick black nylon was used.